AGRONOMICSUPPORT

YOU CAN TAKETO THE FIELD

12

Jan

2022

Planning for Spring: Planter Maintenance Checklist

You've heard the quote, “Failing to plan is planning to fail.” There is no truer statement when it comes to preparing for planting. Use these tips to set your farm up for success before #Plant22.

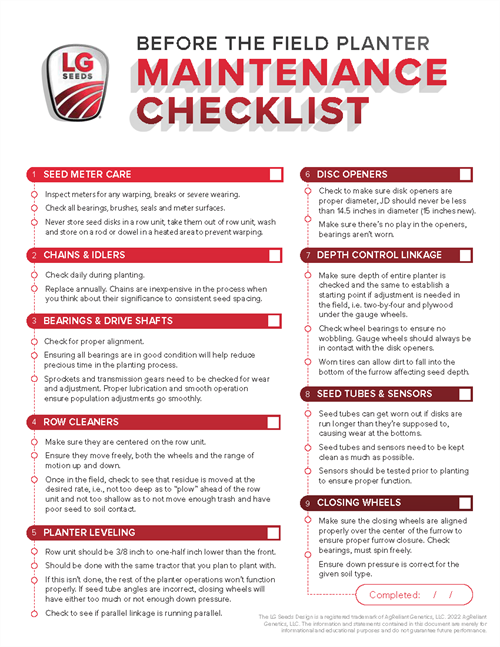

Before The Field: Planter Maintenance Checklist

Seed meter care

- Inspect meters for any warping, breaks or severe wearing.

- Check all bearings, brushes, seals and meter surfaces.

- Never store seed disks in a row unit, take them out of the row unit, wash them and store on a rod or dowel in a heated area to prevent warping.

Chains and idlers

- Check daily during planting.

- Replace annually. Chains are inexpensive, especially compared to their significance in creating consistent seed spacing.

Bearings and drive shafts

- Check for proper alignment.

- Ensure all bearings are in good condition to reduce down time during planting.

- Check sprockets and transmission gears for wear and alignment. Proper lubrication and smooth operation ensure population adjustments go smoothly.

Row cleaners

- Confirm that all row cleaners are centered on the row unit.

- Ensure row cleaners move freely, both the wheels and the range of motion up and down.

- Once in the field, check to see that residue is moved at the desired rate (not too deep as to “plow” ahead of the row unit and not too shallow as to not move enough trash and have poor seed to soil contact).

Planter leveling

- Check this with the same tractor you will plant with.

- Row units should be 3/8” to 1/2” lower than the front.

- Check to confirm parallel linkage is running parallel.

- If this isn’t done, the rest of the planter operations won’t function properly. If the seed tube angles are incorrect, closing wheels will have either too much or not enough down pressure.

Disc openers

- Check to confirm disk openers are the proper diameter, most should never be less than 14.5” in diameter (15” when new).

- Make sure there’s no play in the openers and bearings aren’t worn.

Depth control linkage

- Make sure the depth of the entire planter is checked and the same. This will establish a starting point if adjustments are needed in the field. Use 2x4 and plywood under the gauge wheels.

- Check wheel bearings to ensure there is no wobbling. Gauge wheels should always be in contact with the disk openers.

- Worn tires can allow dirt to fall into the bottom of the furrow affecting seed depth.

Seed tubes and sensors

- Seed tubes can get worn out if disks are used beyond their lifespan, causing wear at the bottoms.

- Seed tubes and sensors need to be kept as clean as possible.

- Sensors should be tested prior to planting to ensure proper function.

Closing wheels

- Make sure the closing wheels are aligned properly over the center of the furrow to ensure proper furrow closure.

- Check bearings to ensure they're free spinning

- Ensure down pressure is correct for the given soil type you're planting in.

We're there when you need us – with all the seed, trait and treatment choices, and none of the distractions. Get in touch today.